- To display daily and cumulative Production Target Vs Achievement

- To display % achievements till date of different teams & total.

- To display loss of production time in minutes /hours ,day wise, month wise

- To display % Variation, % Efficiency, day/week/month wise

- To display safety messages, welfare messages

- To display greetings message for a day i.e. Birthday, Welcome, Appraisal etc.

- Today’s visitors information on the shop floor

Industrial Displays

In Industrial applications Durability and Ruggedness is of utmost important. Taking this point into consideration, Axis Technologies has always focused on providing the best and rugged solutions suitable for industrial applications.

The main objective of these Industrial Displays is to provide online production information and status on the shop floor. This online information helps to take appropriate action by the concerned managers to achieve their targets and objectives. The system also communicates important messages.

Also for industrial applications, Axis Technologies has always designed best quality solutions which can withstand in the industrial environment and conditions, without any maintenance and trouble. These displays work superior and efficiently in the industrial environment, where the conditions are different from the normal environmental conditions.

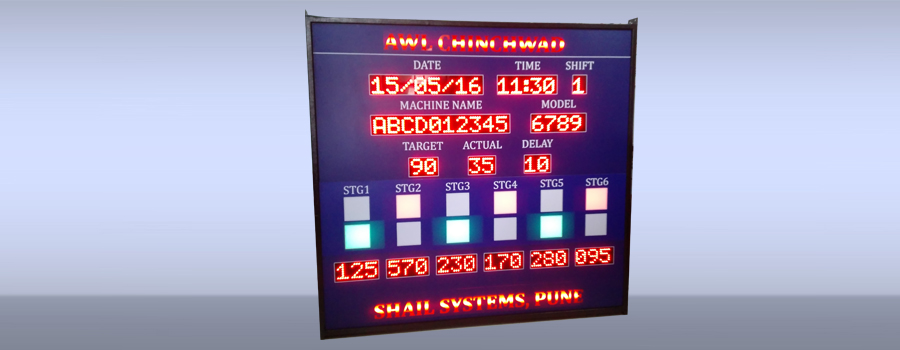

ANDON DISPLAY

ANDON Displays and Production display boards have been well accepted as an effective management tool in industries. ANDON Displays are used to show the Production data & status of the machine, line or process

These displays help Production and shop floor managers to identify where one need to concentrate efforts, to get maximum efficiency from production lines and shop floor. The main objective of these ANDONs is to provide online production information and status on the shop floor. This information is such as target, achievements, Shift Count, Difference, % variation and % Efficiency etc. This online information helps to take appropriate action by the concerned managers to achieve their targets and objectives. The system is also useful to display and communicate important messages as safety messages, welfare messages, and greetings to all concerned within no time.

Axis Technologies is leading manufacturer and supplier of ANDON Display Boards. These boards are supreme in quality and ensure finer performance. Further, these can be manufactured as per the details specified by our client to meet the exact needs of our prestige clients.

APPLICATIONS

SPECIFICATIONS

- Single Sided/ Double Sided Visibility

- Indoor/ Outdoor applications

- Combination of Numeric and Alphanumeric data

- Standard Numeric Digit Heights 1”, 2” , 4”, 6”, 8”, 10”, 12”

- Customized Digit Heights are also Possible

- Audio Indications for Alarms

- 230V Single Phase A.C. Mains Operated systems

- Communication Interfaces: RS232, Ethernet, WIFI, RS485, ModBus Serial, MODBUS TCP/IP, CANBUS, PROFINET/ PROFIBUS, Zigbee

- Better visibility through Imported Acrylic Sheet

- MS fabrication with powder Coating

- Mounting- Wall mounted/ Hanging

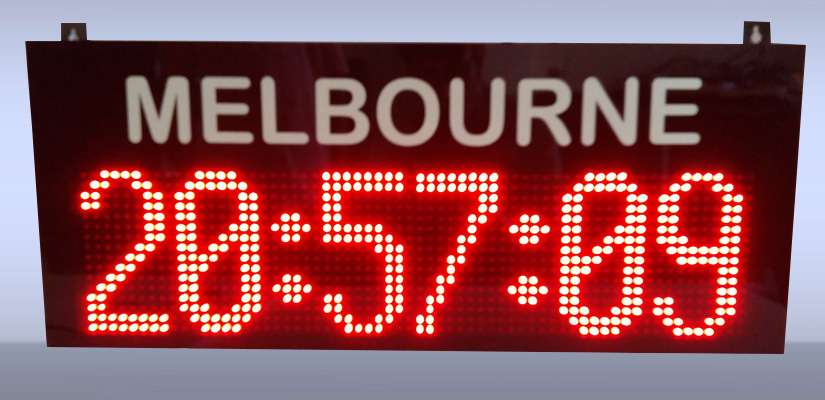

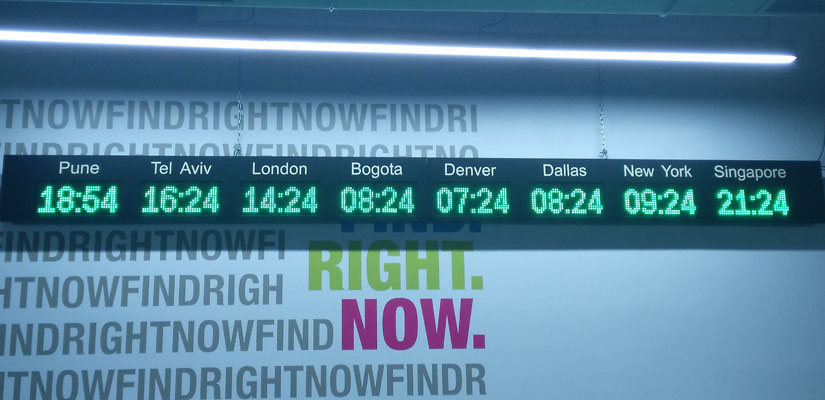

CLOCKS

Axis Technologies is leading manufacturer and supplier of Synchronized/ Stand alone digital clocks to various industrial verticals. Our extensive array of digital clocks is offered in two types of display options as bar LED type (module) and discrete LED type.

The clients have range of options to choose from depending upon their requirements and budget. These clocks are available with various digit heights sizes as 1”, 2”, 3”, 4”, 6”, 8”, 10” 12”, 24”.Also in customer specific requirements the digit size can be manufactured to suit the client’s need.

These clocks can be broadly categorized as

1. GPS Synchronized array of Master-Slave Clocks

2. NTP Server Synchronized array of Master-Slave Clocks

3. Stand Alone Clocks

1. GPS Synchronized Array Of Master-Slave Clocks

In this category, master clock will receive the time from satellite using GPS. All slave clocks time is synchronized with time of master clock. The connection interface between Master clock and slave clock can be any of the following

Communication Interfaces: Ethernet, WIFI, RS485

2. Server Synchronized Array Of Master-Slave Clocks

In this category all the clocks will act as a slave and NTP server will be master. All the clocks will receive the time from NTP server and synchronized with its time. The connection interface between NTP server and slave clock can be any of the following

Communication Interfaces: Ethernet, WIFI

3. Stand Alone Clock

Stand alone clocks are useful where synchronization between two clocks is not required and essential. The setting of time can be done using keypad provided on clock or from using PC

Applications of clock Displays

- To maintain uniformity with respect to time throughout company.

- To avoid miscommunication about Time.

- To indicate with an audio alarm facility where ever required e.g. Tea time, Lunch time etc.

- In Industries

- In Corporate offices

- In government offices

- In Schools and Universities

- In Hospitals

- At Public Places

Specifications

- 5V/12V/24V D.C. operated

- No setting required

- Keeps time in Power failures

- 12/24 Hours options with Either HH:MM or HH:MM:SS format

- Blinking Separator in between HH ,MM and SS

- Global clock settable option ( Clock of Different counties can be shown)

- Standard Digit Size available is 1.5”,2.3”,4” ,6”,8”,10”,12”

- Custom made sizes can be designed as per client specific need

- Standard Colors available – Red, Green, Orange

- MS fabrication with powder Coating

- Mounting- Wall mounted or Hanging

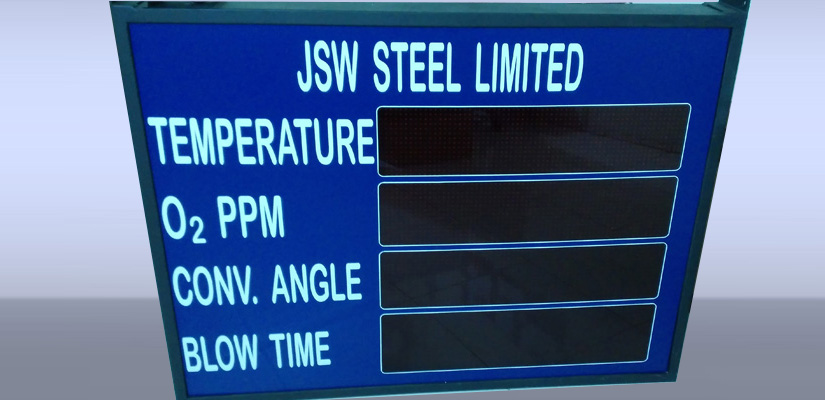

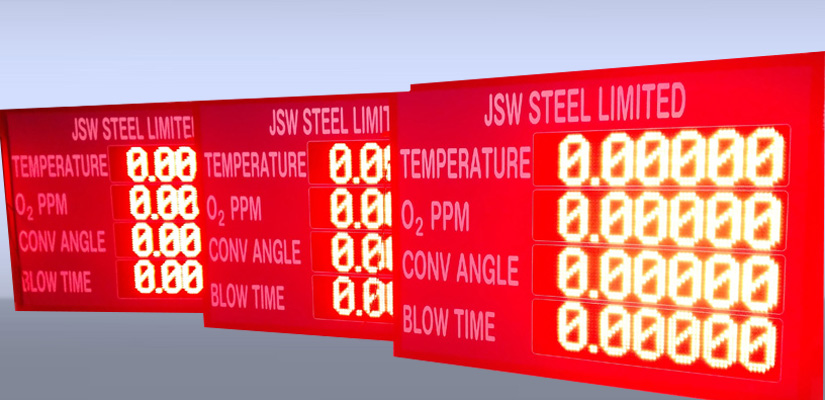

Parameter display

Monitoring of various parameters is important aspect in various Industry Verticals. These parameters can be displayed on ANDON display. These displays are used to show parameters of any machine or process. Various parameters which can be shown are Temperature, Humidity, Level, Flow, Weight, Pressure, Force, RPM, Speed, Current, Voltage, Counter and So many.

Axis Technologies provides Parameter Display Solutions to various industry verticals. These displays can be custom-built and can take inputs from Axis make Data loggers or Client’s own instruments or third party Data loggers/ Analyzers systems. Inputs or Communication interfaces to these displays can be of various types as follows

Input Methods / (Communication Protocols)

- 4to 20mA analog input

- Analog Voltage input with Various ranges

- Digital Pulse Input

- Digital data input using RS232, Ethernet, WIFI, RS485, ModBus Serial, MODBUS TCP/IP, CANBUS, PROFINET/ PROFIBUS Protocols

APPLICATIONS

- In Process industries

- In Pharmaceutical Companies

- In Cold storages

- In Dairies and Milk Chillers

- In Food Industries

- In Foundries and Steel Plants

Weather and Air Qulity Display

To create awareness about conservation of nature and environment is need of the time. To prevent pollution, air quality monitoring and Display it to the public at various public places and traffic signals can create good impact.

Axis Technologies provide various custom built Display Solutions to convey these Weather and Air Quality parameters. These boards can be also effective in display scrollings of various types of messages like Public & Road Safety messages, Pollution Control Messages, General and Social Awareness Messages. These displays also have the built-in capability to display online parameters whereas the displays can capture the data from the Air Parameter and Pollution analyzers.

The protocol Interface with Pollution Parameter analyzers can be any of the following

Communication Interfaces: RS232, Ethernet, WIFI, RS485, ModBus Serial, MODBUS TCP/IP, CANBUS, PROFINET/ PROFIBUS, Zigbee

Stoppage display

Assembly Line Stoppage Display

Assembly Line Stoppage Display is useful to show stoppages at individual stations or at stages in production line along with the delay caused due to these stoppages.

There can be multiple issues and reasons causing Line Stoppage Such as - Maintenance, Quality, Material shortage, Emergency, etc. These issues can be logged to central Server and used for report generation. This display can show current production status and variance. These reports can be emailed to concern managers and authorized persons automatically

- Communication Interfaces: RS232, Ethernet, WIFI, RS485, ModBus Serial, MODBUS TCP/IP, CANBUS, PROFINET/ PROFIBUS, Device net, Zigbee

Internet Connectivity and IoT features can be added in these Displays

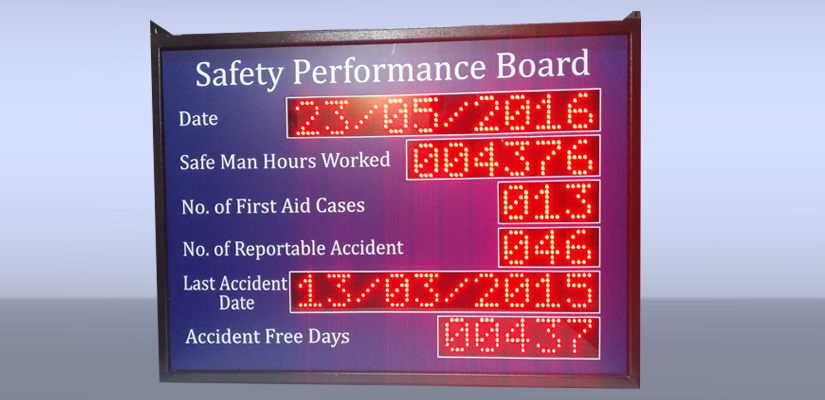

Safety Display

Safety Display Boards (Accident Free Days Display Board)

These Display Boards are used to show total non accident free days counted in plant. This display runs on RTC (Real Time Clock). User can set target value from PC software utility and actual Days will be incremented automatically everyday.

The display can also show other values such as

Date

Safe Man Hours Worked

No. of First Aid Cases

No. of Reportable Accident

Last Accident Date

Total Accident Free Days

(020) 65108555